The Ector County Utility District master plan recommended system improvements to expand service capabilities and increase redundancy...

Cost Savings

Analyzed unique hydraulic challenges and options for pumping downhill, designing a solution that saved the client approximately $110 million compared to a deep tunnel gravity option

Design for the End User

Performed a detailed downstream hydraulic control evaluation, leading to the implementation of an underground “standpipe” that simplified lift station operations and maximized reliability

Unique Solution

Developed a peak flow lift station that skims wastewater from two existing 48-inch interceptors, pumping around a system choke point to mitigate downstream overflows

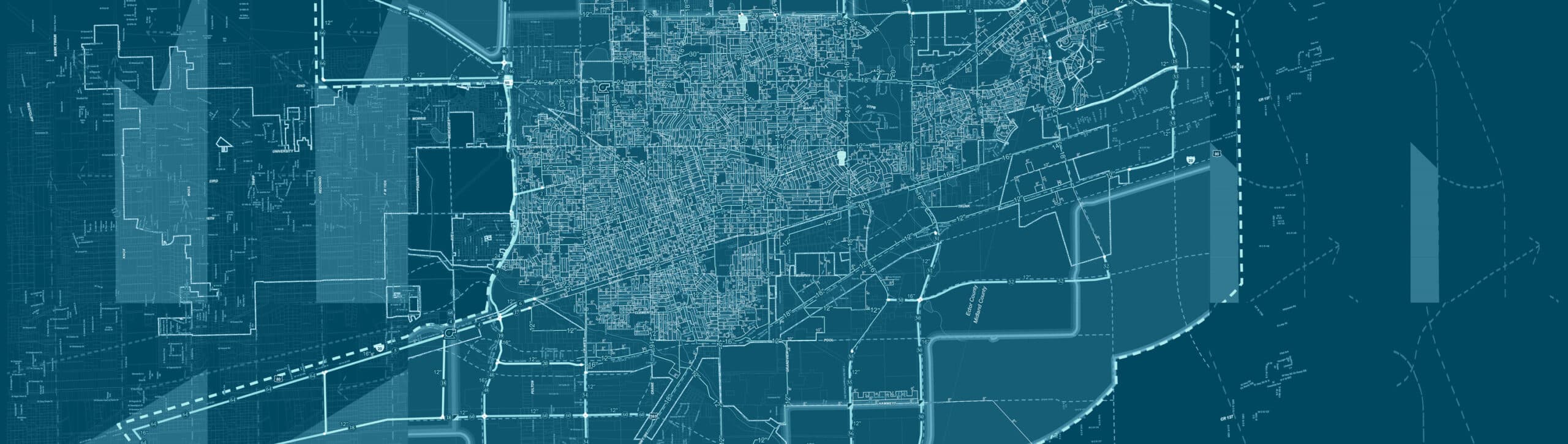

With nearly 1 million residents, Fort Worth is recognized as the 12th most populous US city and has grown at a rapid 6.5% pace over the past four years. Along with this population growth comes increases in wastewater discharge and strain on the city’s wastewater collections system.

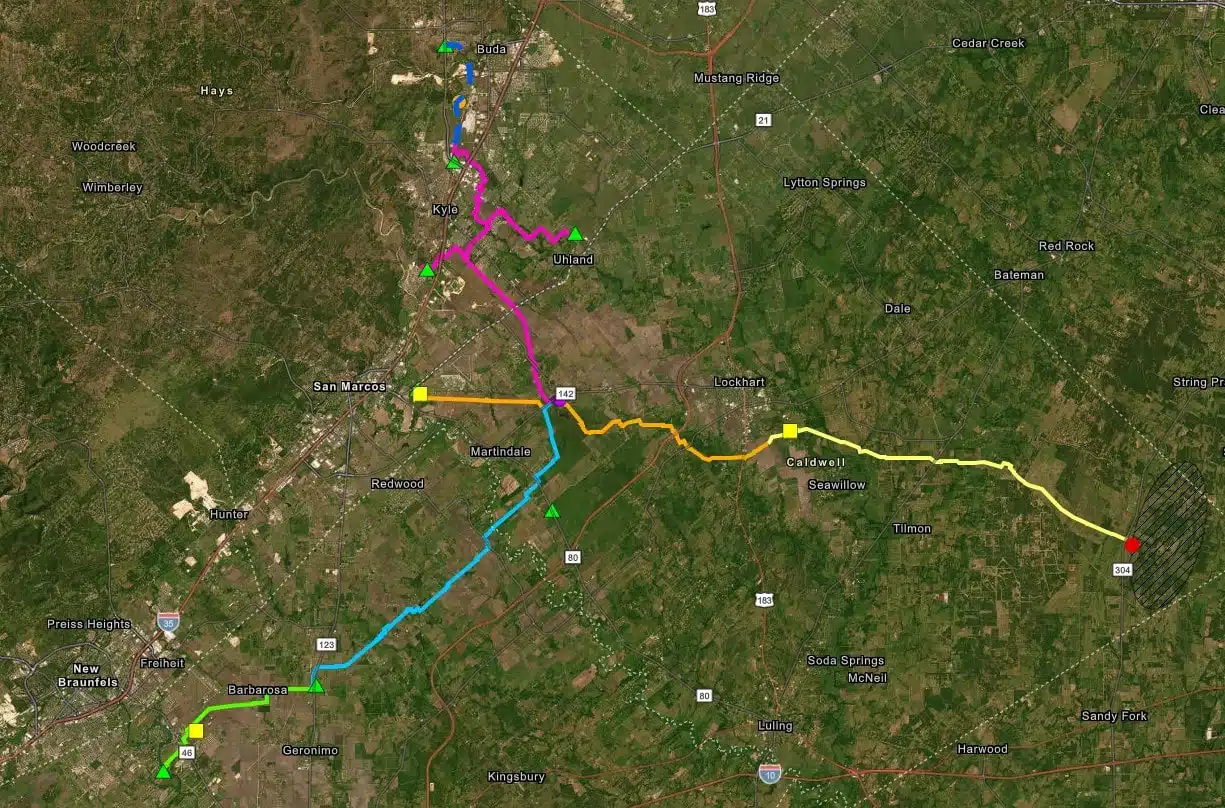

Approximately 100,000 acres in Fort Worth drain into the Clear Fork sanitary sewer basin, and all of this area drains into two 48-inch interceptors near South University Drive and Interstate Highway 30. Continued growth has led to multiple sanitary sewer overflows (SSOs) in this area due to multiple capacity constraints within the collections system.

Recognizing the severity of the SSOs and the need to pursue corrective measures, the City of Fort Worth included the Clear Fork Lift Station and Force Main project as one of several planned sanitary sewer overflow initiative projects in a formal agreement with the Texas Commission on Environmental Quality in 2018.

Kimley-Horn assisted the City of Fort Worth with all design aspects of this project and obtained nine permits/license agreements from the United States Army Corps of Engineers, Tarrant Regional Water District, Texas Department of Transportation, Union Pacific Railroad, North Texas Tollway Authority, Fort Worth and Western Railroad, and Fort Worth Parks and Recreation Department. Our team provided the following services:

- Alignment evaluation

- Pipeline design and engineering

- Lift station design and engineering

- Resident project representative services

Navigating Through Project Constraints

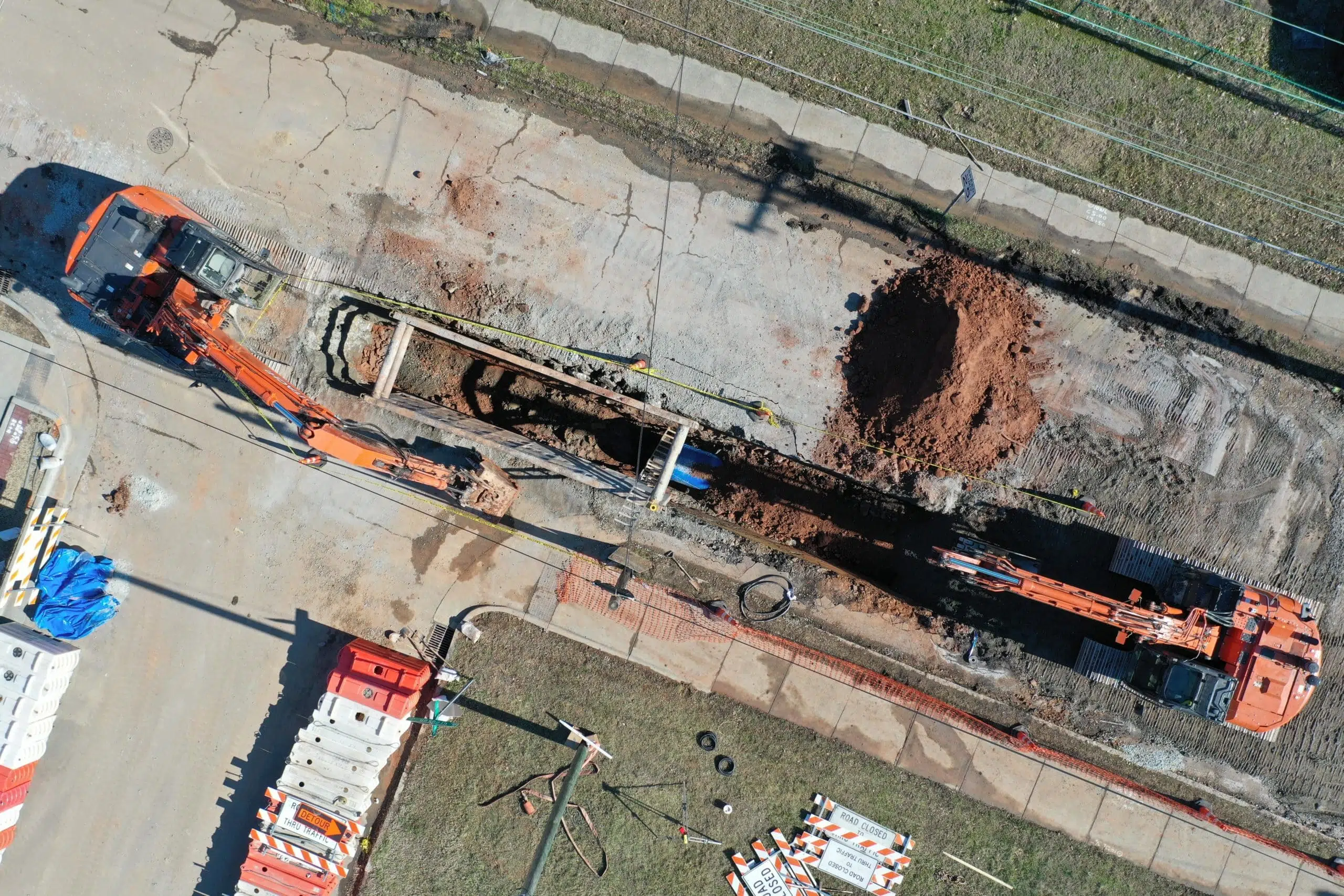

Initially, a gravity pipeline was proposed as the best solution for capacity improvements. However, as part of a previous project, Kimley-Horn assisted the City of Fort Worth with an alignment study for the proposed relief interceptor. The study identified horizontal and vertical constraints in a densely developed part of Fort Worth, which would not permit larger gravity interceptors to be installed without lowering the new interceptor significantly. The additional depths as well as various horizontal constraints would require the pipeline to be installed mostly by trenchless methods. As a result, the proposed project was projected to cost $150 million, which was more than triple the anticipated cost identified in the City’s wastewater master plan.

The City of Fort Worth acknowledged these limiting factors and requested Kimley-Horn finalize the alignment study by evaluating the feasibility of a pumping alternative. As a result of the analysis, it was determined that a peak flow lift station and force main could mitigate overflow concerns during peak wet weather conditions for approximately $40 million—resulting in significant cost savings.

Analyzing Options for Optimal System Functionality

Once the City of Fort Worth and Kimley-Horn decided on the force main and lift station solution, our team needed to perform additional analyses to ensure that the system could work within the given constraints. Typically, lift stations are located at the bottom of a basin, and then the force main transports the wastewater up from the basin to the associated discharge area, where flow converts back to gravity. However, in this scenario, the discharge location was approximately 35 feet lower than the proposed lift station—prompting the team to think through creative ways to evaluate friction during both steady state and filling conditions.

The City wanted the lift station to have the flexibility to pump between 8 and 22 MGD. However, modeling determined that on the downhill legs in lower flow scenarios, two problems might occur. The hydraulic grade line could dip beneath the pipeline, or the downhill legs could become inoperable under pressure—both of which could be mitigated by combination air/vacuum valves (CAVs). On a typical station that operates regularly, issues with CAVs would be immediately apparent. However, given that this station would only operate during peak wet weather events, system problems would not become apparent until it was too late.

To allow for downhill pumping, options to increase system friction were investigated, including the following:

- A positive displacement jockey pump

- A motor actuated valve at the force main discharge area

- A sewer pressure sustaining valve at the force main discharge area

- A standpipe at the force main discharge area

These different options, which would increase system friction and a water column through the force main, were ultimately not selected for the project. However, upon further evaluation of the various options above, it was determined that instead of directly discharging the force main into the intended discharge point, an adjacent hill permitted the force main to discharge at a much higher elevation, before discharging to gravity. The force main would then discharge near the same elevation as the lift station site, transitioning to a gravity line back down the hill to the intended discharge point. The selected solution was effectively an underground “standpipe” and permitted much simpler operation of the system.

Solutions to Mitigate Sanitary Sewer Overflows

Kimley-Horn’s solution to the chokepoints in the gravity system involved leveraging the existing interceptors—rather than upsizing or replacing them—and implementing a peak flow 22 MGD lift station and force main. The team was able to achieve the City’s preferred flow range with an underground standpipe, which allows for streamlined hydraulics and eliminates the need to solely rely on CAVs. The lift station will skim wastewater from two parallel sanitary sewer lines, lower the hydraulic grade line of the system, and eliminate SSOs in South University Drive. The associated force main is 14,000 linear feet of 36-inch high-density polyethylene pipe (DR-13.5 and DR-11), and was installed via several methods, including open cut, hand tunneling, and horizontal directional drilling.

This partnership with the City of Fort Worth resulted in our design of unique system hydraulics to overcome the downhill pumping obstacle. Additionally, since we selected a pressurized pipeline installation over the gravity line placement, the construction process was much more flexible and minimized the project’s impact to the surrounding area.

The Clear Fork Lift Station and Force Main project was completed in summer of 2024. The complex corridor of interwoven utility infrastructure now hosts an innovative solution to a longstanding SSO—one that sets a precedent for other capacity-constrained wastewater systems down the pipeline.